Isakhiwo Sesakhiwo Sensimbi Eningi Sezitezi & Ihhotela &Ihhovisi & Isikole & Nelabhulali & Nesikhungo Sokuthenga Isakhiwo Sensimbi Ephakeme

Izici Zokwakheka Kwezindaba Eziningi

I-1.Insimbi enkulu ye-ductility, ukusebenza kahle kokuzamazama komhlaba kwesakhiwo

I-2.Isisindo esilula, isisindo sesakhiwo sensimbi isakhiwo eside singaba ngu-60% wesakhiwo sikakhonkolo, esinganciphisa kakhulu izindleko zesisekelo nesakhiwo.

I-3.Isikhathi esifushane sokwakha, isivinini sokwakhiwa kwesakhiwo sensimbi cishe izikhathi ezingu-1.5 ngokushesha kunesakhiwo sokhonkolo esiqinisiwe ngenxa yezinga eliphezulu le-factorization.

4.Indawo yesakhiwo esincane, indawo yekholomu yensimbi cishe i-1/3 yekholomu kakhonkolo futhi yonga u-3% wendawo yokwakha.

5.Yehlisa ukuphakama kwesitezi, izingxenye zensimbi yensimbi ngokuvamile zimfushane kunokhonkolo futhi ipayipi lingadlula kuwebhu yensimbi yensimbi.Ukuphakama okufanayo kuvumela izitezi ezengeziwe ukuba zenzelwe ukwandisa indawo yaphansi.

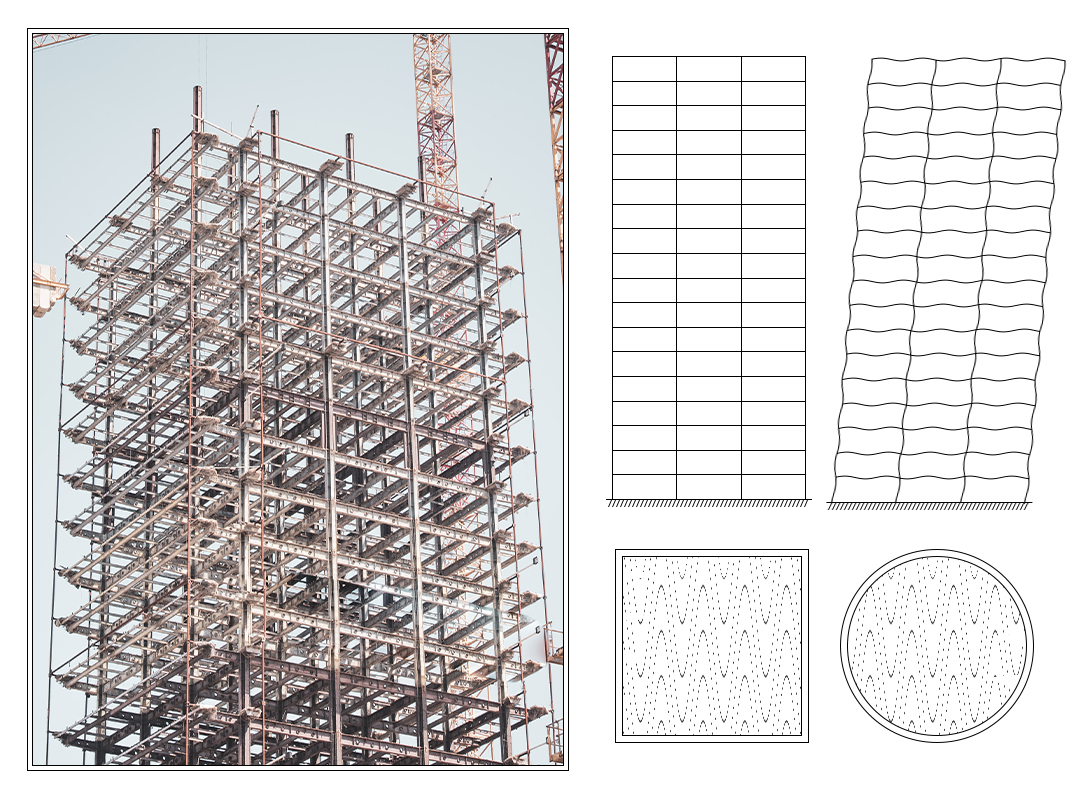

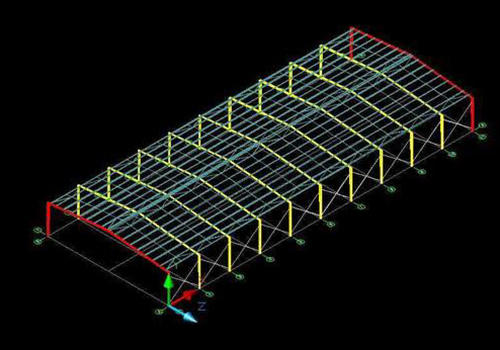

Isakhiwo sohlaka

1.Uhlaka lwakhiwe ngamakholomu nemishayo, olunamandla aqondile namacele

2. Ukusebenza kohlaka oluqinile ngokumelene namandla ahlangene akukuhle, ukuchezuka kwesakhiwo kukhulu, ngokuvamile kulungele ukwakheka kwezindaba ezingaphansi kwezingu-20.

3.Ikholomu ngokuvamile isebenzisa ikholomu yensimbi yebhokisi noma ikholomu yeshubhu yensimbi egcwele ukhonkolo

I-4.Ikholomu ye-tubular yensimbi egcwele ukhonkolo igcwele ukhonkolo embhobheni oyindilinga noma ikholomu yebhokisi, engenazo nje izinzuzo zesakhiwo sensimbi, kodwa futhi isebenzisa ngokugcwele izakhiwo ezinhle zokucindezela ukhonkolo.

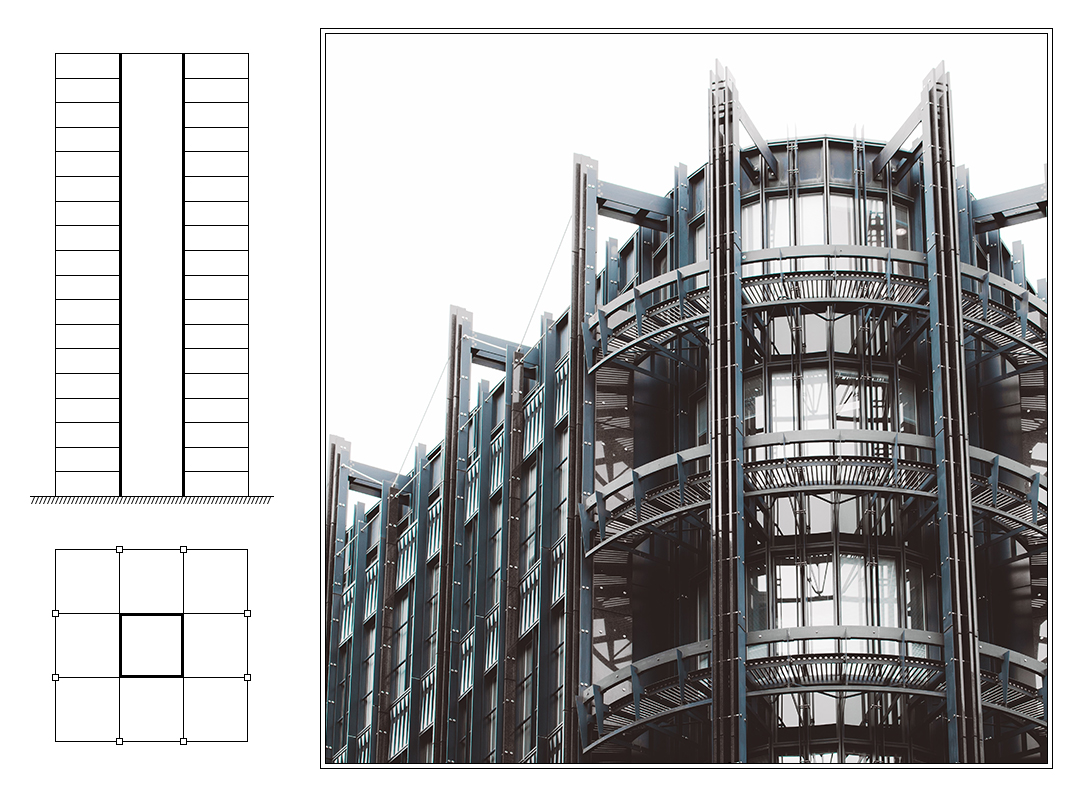

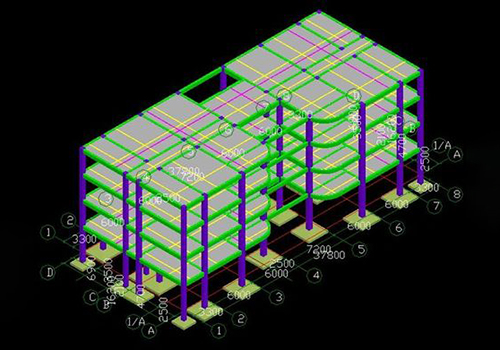

Isakhiwo se-Framed-Tube

1.Lolu hlobo lwesistimu yesakhiwo ngokuvamile lwakhiwe ngeshubhu likakhonkolo eliqinisiwe kanye nohlaka lwensimbi lwangaphandle.

I-2.I-tube eyinhloko iyisilinda, i-rectangular noma i-polygonal ezungezwe izindonga zekhonkrithi eziqinisiwe ezingaphezu kwezine, ingaphakathi linikezwa inombolo ethile yezingxenye zekhonkrithi eziqinisiwe ze-longitudinal kanye ne-transverse.Uma isakhiwo siside, inani elithile lamafreyimu ensimbi angase abekwe odongeni oluyisisekelo;

3.Uhlaka lwensimbi lwangaphandle lwenziwe ngekholomu yensimbi nensimbi yensimbi.

4.Ukuchezuka kwesakhiwo kwesakhiwo ikakhulukazi kuvinjelwa ishubhu eliwumgogodla, okuwuhlelo lwesakhiwo olusetshenziswa kakhulu ezakhiweni eziphakeme.

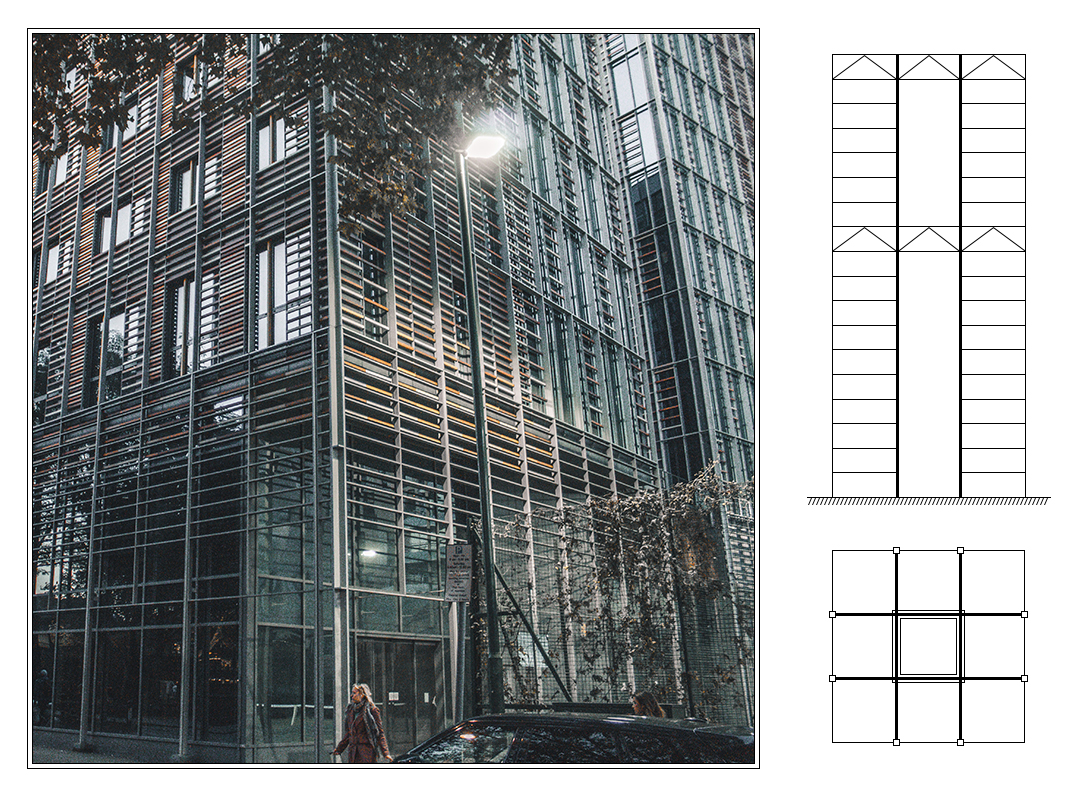

I-Lateral Force Resistance of High - Rise Steel Structure - Outrigger Truss

1.I-Outrigger truss iyisinyathelo esibalulekile sokunciphisa ukuchezuka kwezakhiwo eziphakeme kakhulu

2.Ama-Outrigger trusses ngokuvamile atholakala phansi kwemishini noma endaweni yesiphephelo, ububanzi kuya kububanzi obugcwele bendlu, ukuphakama kuyisitezi esisodwa noma ezimbili ukuphakama, ngokuvamile kumiswa amasitezi amathathu kuya kwezine kuwo wonke ubude bephansi.

3. Umgomo we-outrigger truss ukuthi lapho isakhiwo sibhekene nokuchezuka kwe-lateral, amandla e-axial tension wekholomu yangaphandle yensimbi akhipha i-torque ehlanekezela ku-outrigger truss ukuze kuncishiswe ukuchezuka kwe-lateral.

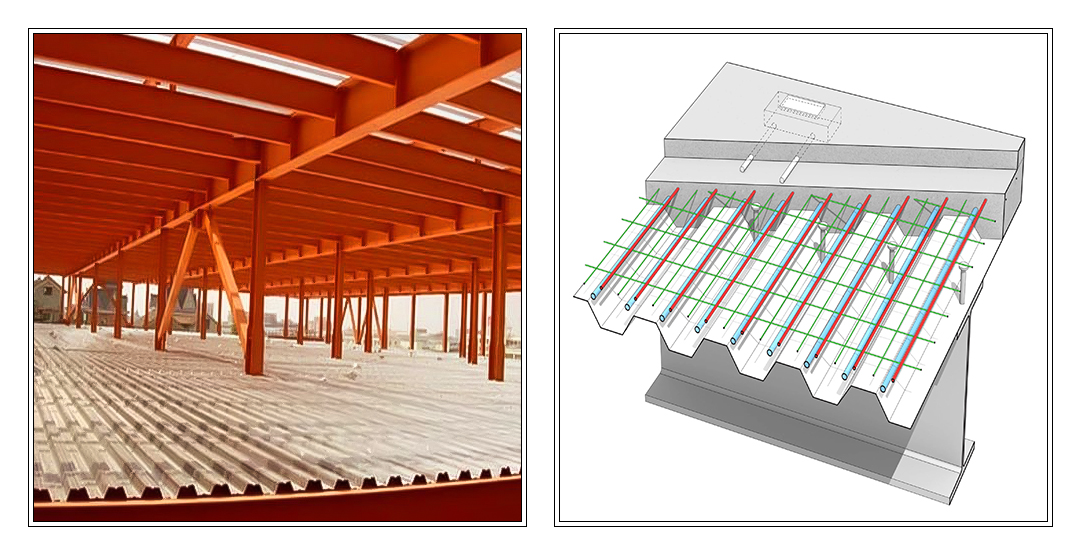

I-Floor Bearing Plate

I-1.Ukuze kugqanyiswe inzuzo yejubane lokwakha elisheshayo lesakhiwo sensimbi, ipuleti elithwala phansi livame ukusetshenziswa esakhiweni sensimbi esiphezulu.

2.Uma usebenzisa i-floor bearing plate, i-scaffolding noma ibhodi lefomu ayidingeki.Ipuleti eliphethe phansi lingasetshenziswa njengebhodi lefomu elihlala njalo, okuyisivinini esikhulu sokwakha futhi lingabuyisela ingxenye yokuqinisa phansi.

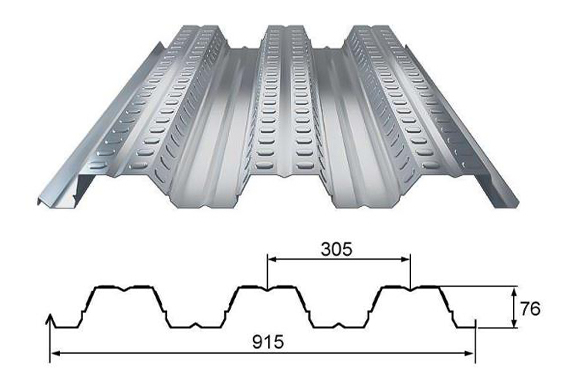

I-3.Floor bearing plate ivame ukuvuleka, ivaliwe, izinhlobo ze-truss

I-Floor Bearing Plate

| Ukuthwala umthamo |

|

| Ukusebenza kokuvikela umlilo | Ipuleti eliphethe phansi alikwazi ukumelana nomlilo, iphansi lepuleti lidinga ukuqiniswa, ipuleti eliphethe phansi alidingi ukuxubha okunamathelayo |

| Ukwakha | Isivinini sokubeka i-floor bearing plate siyashesha, kodwa ukubopha ibha yensimbi kuhamba kancane |

| Sebenzisa | Iphansi lephansi linomumo wegagasi, limahhadlahhadla futhi alilingani futhi ukubukeka akusheleli ngokwanele |

| Umnotho | Izinga lokusebenzisa uhlobo lwe-floor slab liphezulu futhi liphansi.ikhefu eliphansi linciphisa inani likakhonkolo elisetshenziswa phansi cishe ngama-25, linciphisa isisindo sesakhiwo, liphinde lisindise isakhiwo esikhulu nezindleko eziyisisekelo. |

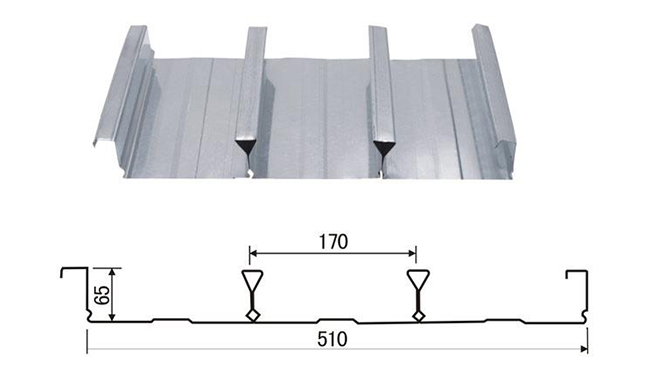

Uhlobo Oluvaliwe Lwe-Floor Bearing Plate

| Ukuthwala umthamo |

|

| Ukusebenza kokuvikela umlilo | Ipuleti eliphethe phansi alikwazi ukumelana nomlilo, iphansi lepuleti lidinga ukuqiniswa, ipuleti eliphethe phansi alidingi ukuxubha okunamathelayo |

| Ukwakha | Isivinini sokubeka i-floor bearing plate siyashesha, kodwa ukubopha ibha yensimbi kuhamba kancane |

Idizayini eyenziwe ngokwezifiso yamahhala

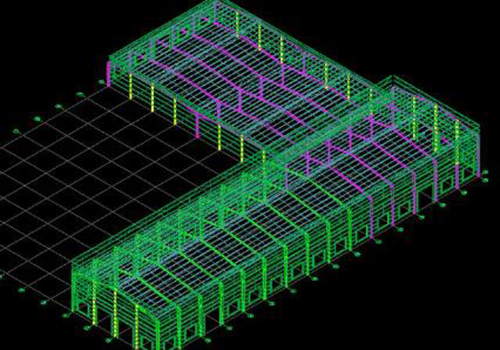

Siklama izakhiwo zezimboni eziyinkimbinkimbi zamakhasimende asebenzisa i-AutoCAD, PKPM, MTS, 3D3S, Tarch, Tekla Structures(Xsteel) nokunye.

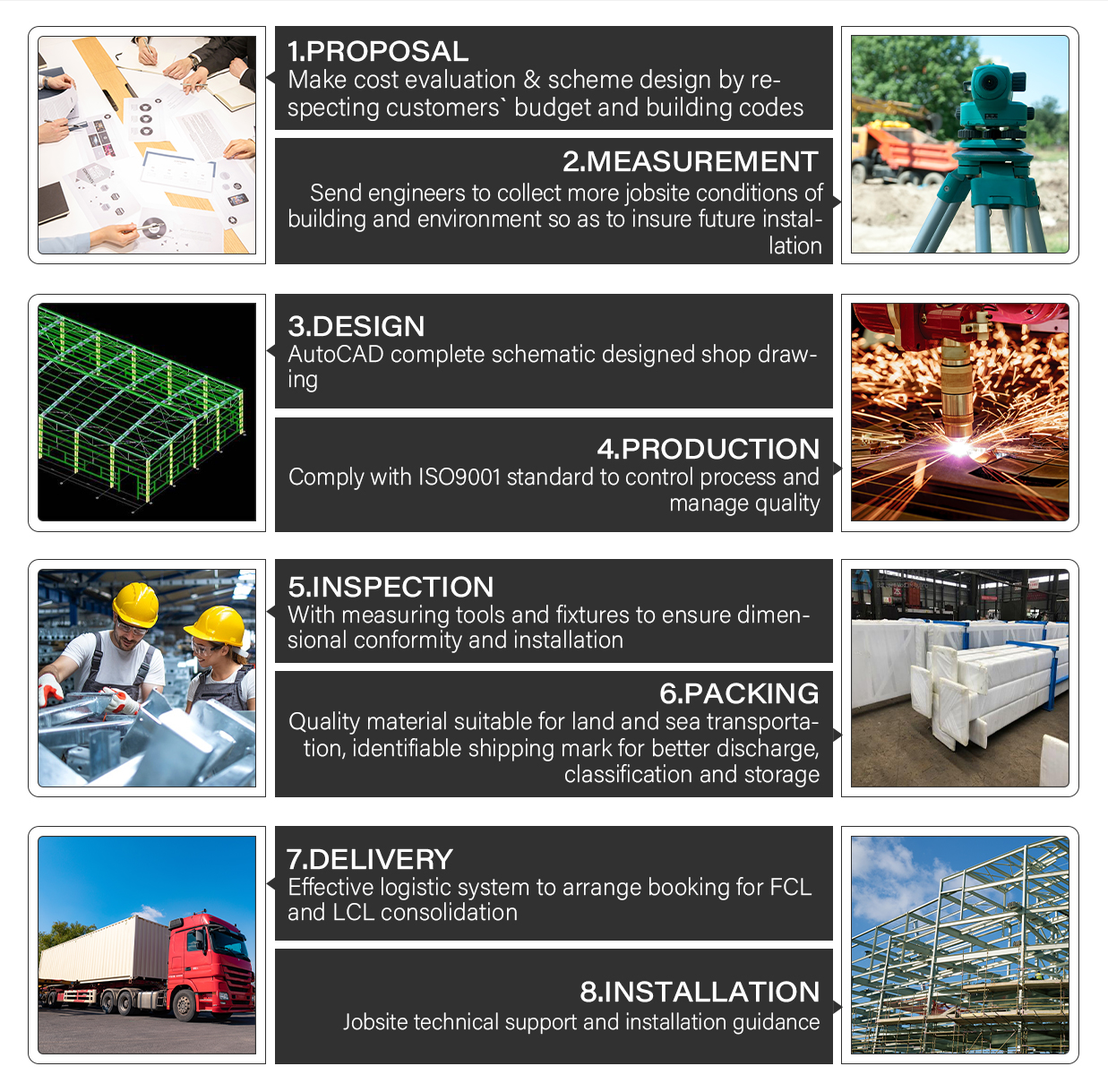

Inqubo yokwenza ngokwezifiso

Ukupakisha Nokuthumela

Isistimu Yokuvala

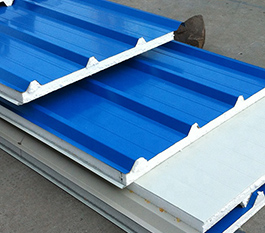

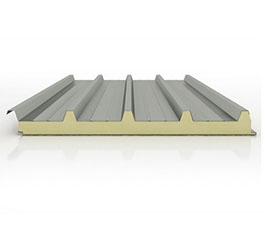

Iphaneli Yophahla

Iphaneli Yophahla

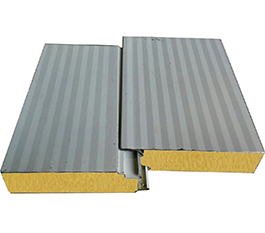

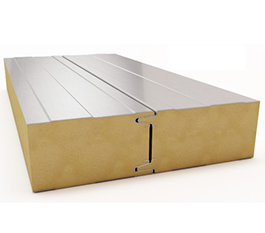

Iphaneli Yodonga

Iphaneli Yodonga

Iphaneli Yodonga

Iphaneli Yophahla

I-Fiber-Glass

Ishidi Lensimbi

Ibholidi

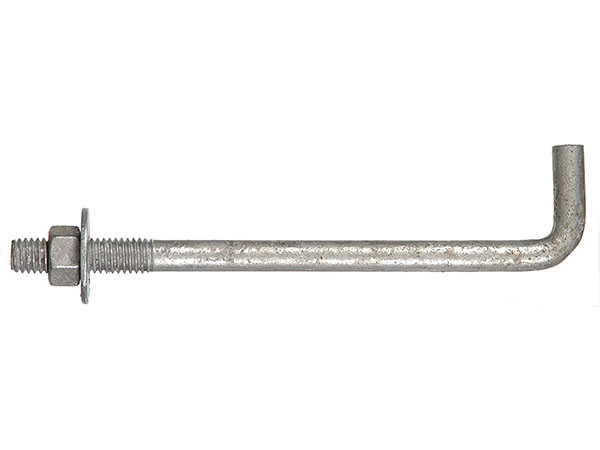

Ibholithi Evunyiwe

I-Expansion Bolt

Self-Tapping Screw

I-High Strength Bolt

Ibhawodi lehange

I-Stud

Imikhiqizo Eyinhloko

Steel Prefab Warehouse

Insimbi Prefab Hangar

Steel Prefab Stadium

I-Bailey Bridge

Isiteshi

Ihholo lokubonisa

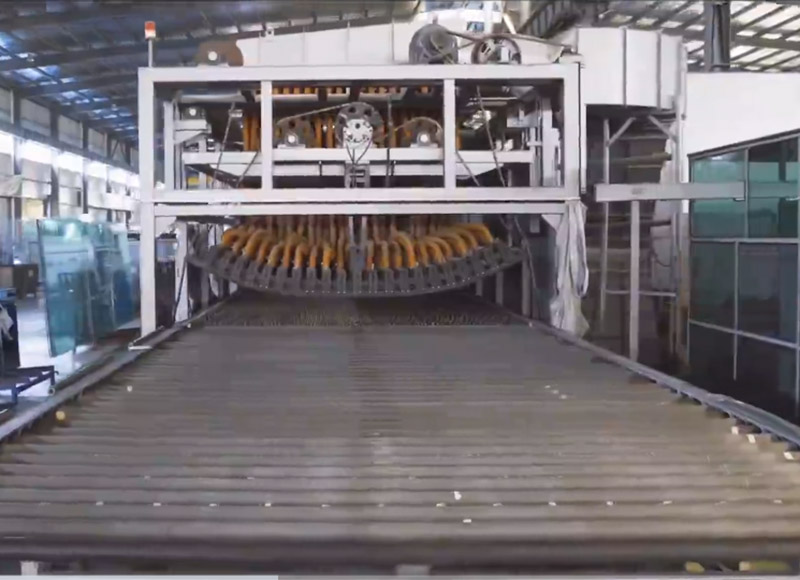

Uhlolojikelele lweworkshop yokukhiqiza

I-Iron Workshop

I-Raw Material Zone 1

I-Aluminium Alloy Workshop

I-Raw Material Zone 2

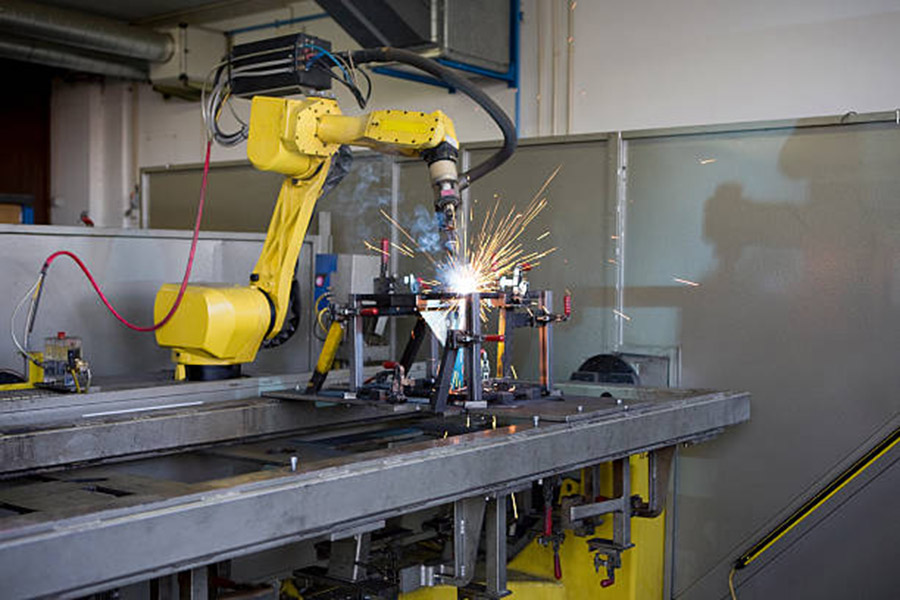

Umshini Wokushisela Irobhothi Ufakwe Embonini Entsha

I-Automatic Spraying Area

Imishini eminingi yokusika

Inqubo Yokukhiqiza

1.Lungiselela Indaba

2.Ukusika

3.Joint

4.Automatic Sub-merged Arc welding

5.Ukuqondisa

6.Izingxenye Ukushisela

7.Ukuqhuma

8.Ukugqoka

Ikhwalithi yokulawula

Ukuhlolwa kwe-ultrasonic weldina

Ukuhlolwa kwe-welding ye-Ultrasonic

Futha ukuhlola upende

Ukuhlolwa kwe-ultrasonic weldina

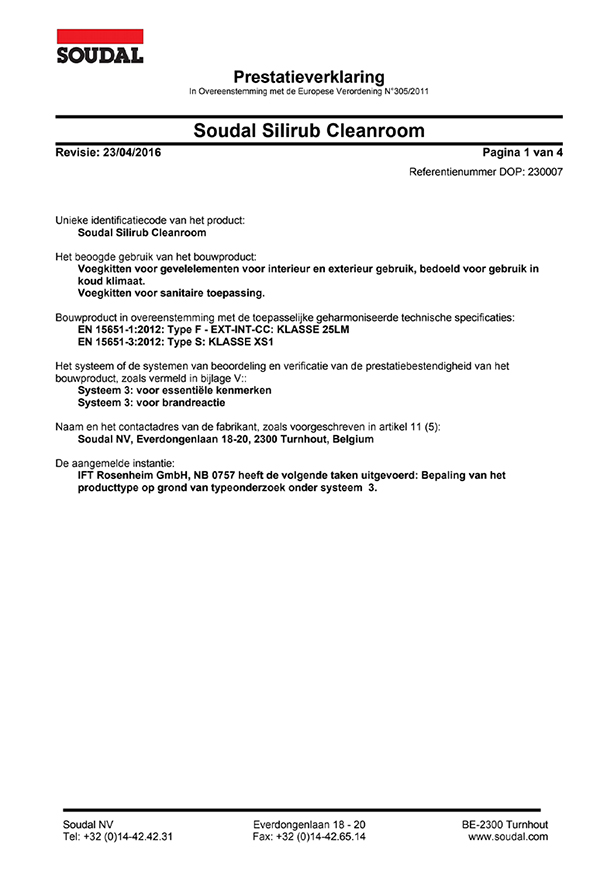

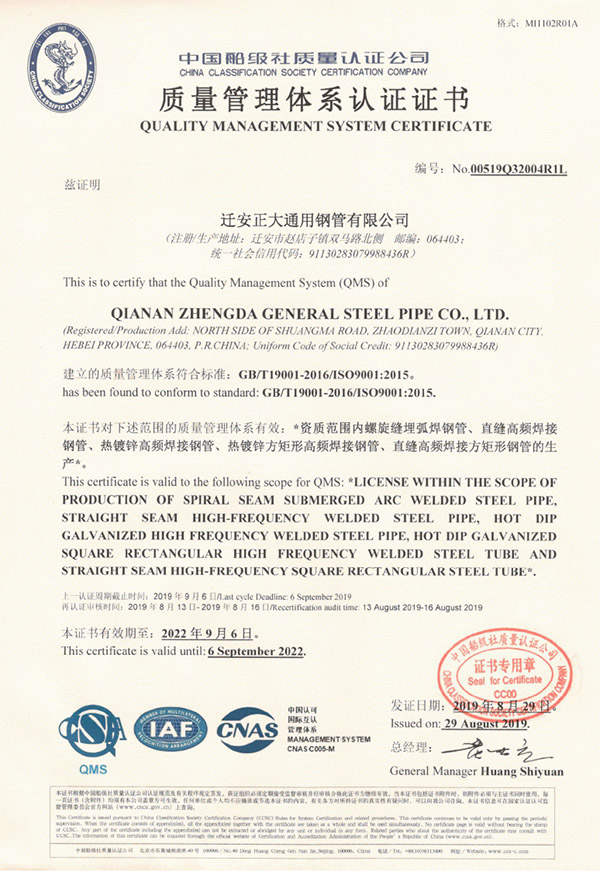

Igunya Lokunikeza Izitifiketi

Inkampani Yokubambisana

FAQ

Q: Ingabe unazo izinsiza zokufaka?

A: Yebo, Sinayo isevisi yokuqondisa yokufaka okudingeka uyikhokhele unjiniyela okuhlanganisa nethikithi le-Visa cost.round trip, ukudla & indawo yokuhlala kanye nemishwalense yasendaweni.

Q: Ungayithola kanjani ikhotheshini enembile?

A: Impilo yokusebenzisa yesakhiwo esiyinhloko impilo esetshenzisiwe eklanyelwe, imvamisa iminyaka engama-50-100 (isicelo esijwayelekile se-GB)

Q: Ingakanani impilo yokusetshenziswa kwekhava yophahla?

A: Isikhathi sokusebenzisa i-PE coating ngokuvamile siyiminyaka eyi-10-25.Impilo yokusetshenziswa kweshidi lokukhanya kwelanga eliphahleni lifushane, ngokuvamile iminyaka engu-8-15

Q: Kuyini ukwelashwa okulwa nokugqwala kwesakhiwo sensimbi?

A: Ukwelashwa kokugqwala kwesakhiwo sensimbi Upende ojwayelekile wokulwa nokugqwala

I-anti-rust paint nge-epoxy zinc primer

I-hot-dip galvanization

I-Hop-dip galvanization + i-PU finish

I-Powder enamathela

Isakhiwo sensimbi engagqwali: No. 301/304/316 isakhiwo sensimbi engagqwali

Q: Sibambisana kanjani kwamanye amaphrojekthi?

A: Sicela imininingwane yephrojekthi kanye nezidingo, sizokwenza idizayini ngokufanele, bese imidwebo yasesitolo idinga ukuhlolwa futhi iqinisekiswe uma kungekho sibuyekezo esisha.ekugcineni senza isivumelwano.