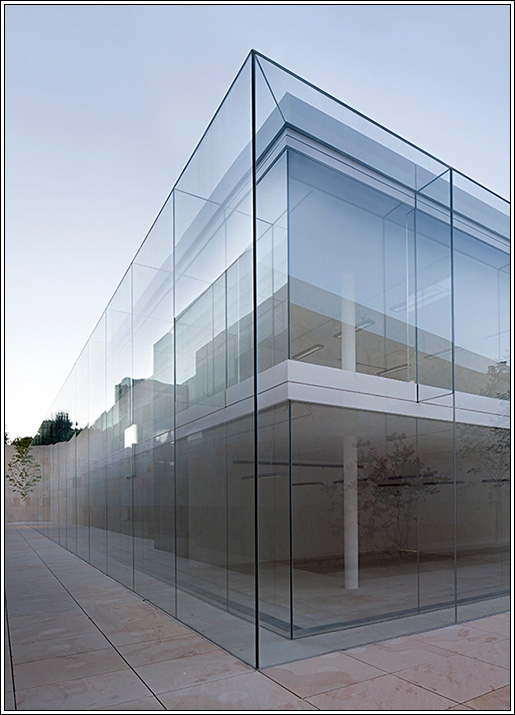

I-Full Glass Curtain Wall System Tempered Cladding Glass Facade Chinese Glass

Isakhiwo sodonga lwamakhethini engilazi egcwele

Kunezinhlobo ezimbili zesakhiwo se-facade yengilazi egcwele, enye inesakhiwo sengilazi enezimbambo, enye ayinayo ingilazi enezimbambo.

Ingilazi enezimbambo: Ukuze uqinise ukuqina kwamaphaneli engilazi, kuyadingeka ukusebenzisa ingilazi ye-strip njengezimbambo zokuqinisa ebangeni elithile, elaziwa ngokuthi ingilazi eyizimbambo.

| Ubude obukhulu be-facade yengilazi egcwele | |||

| Ukujiya kwengilazi(mm) | 10/12 | 15 | 19 |

| Ubude obukhulu(m) | 4 | 5 | 6 |

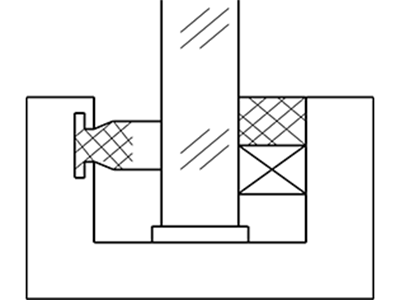

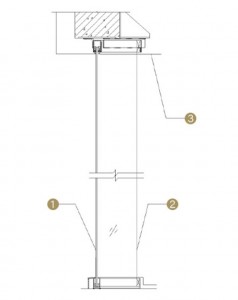

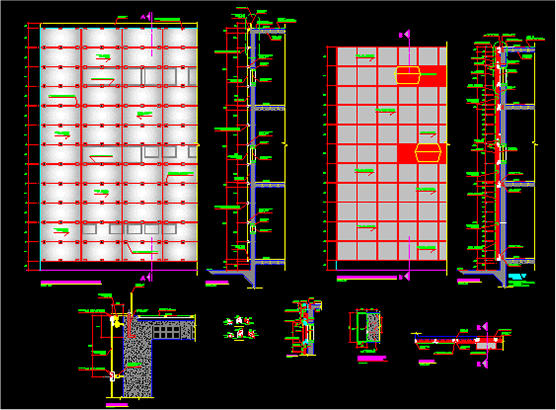

I-facade efakwe phansi yohlobo olugcwele lwengilazi olungaphambili

Incazelo:Lapho ubude bodonga lwamakhethini buphansi, ingilazi engaphezulu kanye nezimbambo kufakwa nomsele ofakwayo, futhi ingilazi igxilile emseleni ofakayo ongezansi, bese kubekelwa eceleni isikhala esithile phakathi kwendawo engaphezulu yomsele ofakwe phezulu kanye nengilazi. , ukuze ingilazi ibe nendawo yokwandisa nokuguqulwa.

Izinzuzo:Isakhiwo esilula, intengo ephansi, incike kakhulu ku-pedestal ukuze ithwale isisindo

Ubuthakathaka:Ingilazi kulula ukugoba kanye nokuguqulwa ngaphansi komthwalo wayo omkhulu, okuholela ekuhlanekeni kwesithombe esibonakalayo.

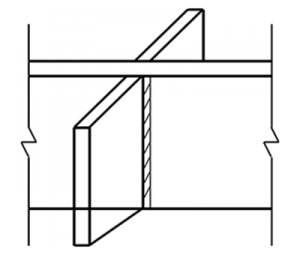

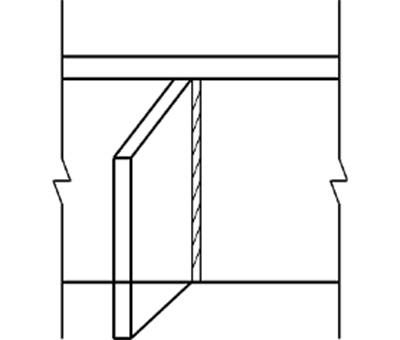

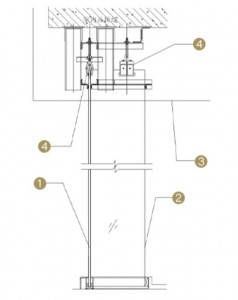

Uhlobo olulengayo olugcwele ingilazi engaphambili

Incazelo:Lapho udonga lwamakhethini luphakeme, ukuze kuvinjwe ingilazi ukuthi ingabhibhi futhi ibhubhiswe ngaphansi komthwalo wayo omkhulu, insimbi ekhethekile isethwe ekugcineni kodonga lwamakhethini, futhi ucezu olukhulu lwengilazi luyalengiswa ukuze lwenze ingilazi eqhubekayo. udonga lwamakhethini ngaphandle kokuguqulwa.Kunesikhala esiguquguqukayo phakathi kwengilazi kanye naphansi komsele ofakwayo.

Izinzuzo:Ingakwazi ukuqeda ukuphambuka kwengilazi okubangelwa ikhwalithi yayo futhi idale umphumela omuhle, obala futhi ophephile.Incike kakhulu ezintweni zensimbi zokuthwala isisindo.

Ubuthakathaka:Isakhiwo siyinkimbinkimbi futhi sibiza kakhulu

Isakhiwo sodonga lwamakhethini engilazi egcwele

Kunezinhlobo ezimbili zesakhiwo se-facade yengilazi egcwele, enye inesakhiwo sengilazi enezimbambo, enye ayinayo ingilazi enezimbambo.

Ingilazi enezimbambo: Ukuze uqinise ukuqina kwamaphaneli engilazi, kuyadingeka ukusebenzisa ingilazi ye-strip njengezimbambo zokuqinisa ebangeni elithile, elaziwa ngokuthi ingilazi eyizimbambo.

| Alukho udonga lwekhethini yengilazi enezimbambo egcwele | |

| Ukwakheka kwenodi | Indlela yokufaka egxilile yengilazi |

| Indlela evamile esetshenziswayo ukufaka iziphetho zengilazi enkulu ohlakeni lwensimbi bese uyilungisa nge-silicone structural sealant. | Kunezinhlobo ezintathu zendlela yokufaka engaguquki yengilazi, umhlangano wohlobo olomile, umhlangano wohlobo olumanzi, Ukuhlanganiswa kokuxuba. |

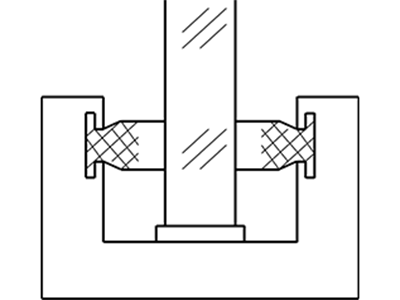

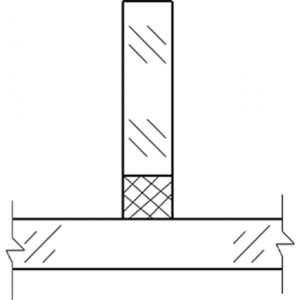

Ukuhlanganiswa kohlobo olomile

Lapho ufaka ingilazi, sebenzisa imicu yokuvala (njengemicu yerabha yokuvala) ukulungisa

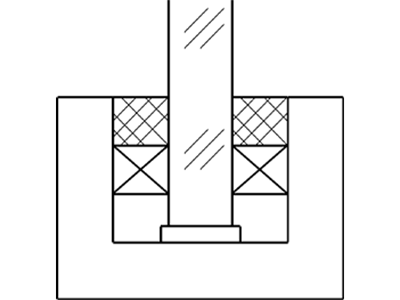

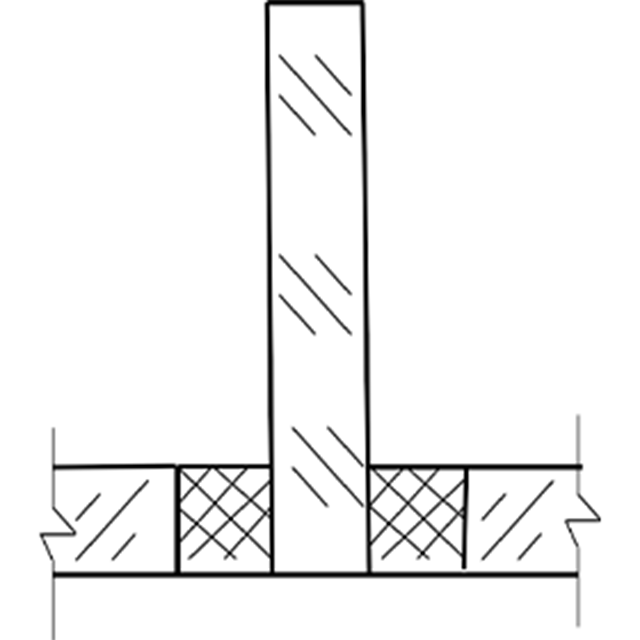

Ukuhlanganiswa kohlobo olumanzi

Ngemuva kokuthi ingilazi ifakwe endaweni, sebenzisa i-sealant (isb. i-silicone sealant) vala igebe phakathi kwengilazi nodonga lwethangi ukuze ulungise.

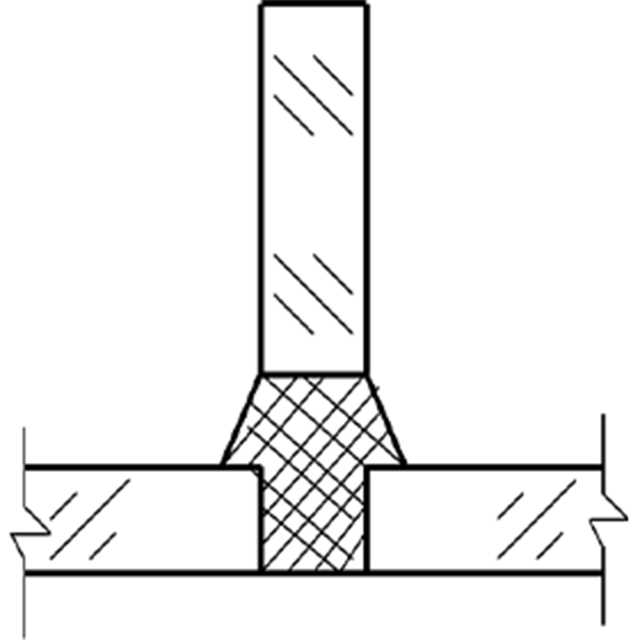

Ukuhlanganiswa kokuhlanganiswa

Ukuhlanganiswa kohlobo olomile kanye nohlobo olumanzi kuhlanganiswe ngesikhathi esifanayo.Okokuqala lungisa umugqa wokuvala ngakolunye uhlangothi, uwufake engilazini, futhi ekugcineni uwulungise ngakolunye uhlangothi nge-silicone sealant.

Qaphela:ukusebenza kokuvalwa kokuhlanganiswa kohlobo olumanzi kungcono kunokuhlanganiswa kohlobo olomile, futhi impilo yesevisi ye-silicone sealant yinde kuneyomugqa wokuvala irabha.

| Ingilazi enezimbambo egcwele udonga lwamakhethini engilazi | |

| Ukwakheka kwendawo ephambanayo yengilazi enezimbambo | |

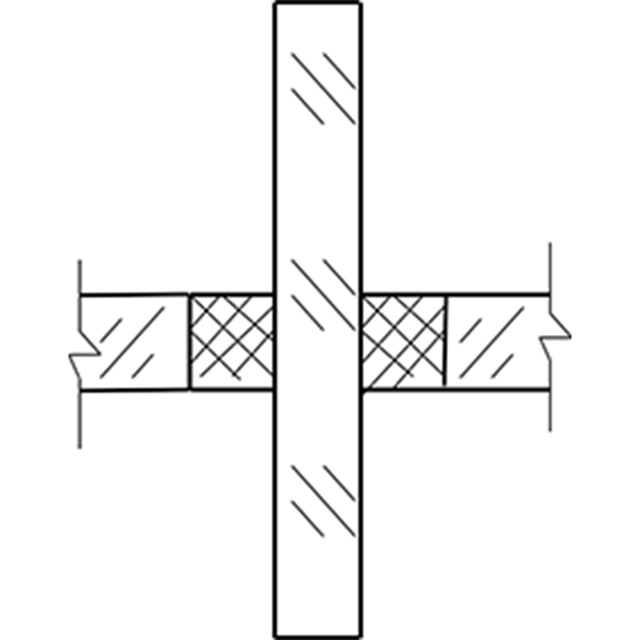

| Ukuqondiswa kwendawo yengilazi yezimbambo kuhlelwe ikakhulukazi ngokuya ngendawo nomsebenzi wokwakha, kanye nezidingo zobuciko.Ngokuvamile kunezindlela ezintathu zesakhiwo eziphathelene nokwelashwa kokuphambana kwemigwaqo kwengilazi yobuso kanye nengilazi enezimbambo: Ukuba nezimbambo ezimbili, izimbambo ezizodwa, Izimbambo. |

Ukuhlanganiswa kohlobo olomile

Ingilazi enezimbambo nhlangothi zombili, ifanele udonga lwangaphakathi oluphakathi

Ukuhlanganiswa kohlobo olumanzi

Ingilazi enezimbambo ngakolunye uhlangothi, ifanele udonga lwangaphandle

Ukuhlanganiswa kokuhlanganiswa

Ingilazi enezimbambo engilazini engaphezulu, ilungele udonga olukhulu lwamakhethini.

| Ukwelashwa kwendawo ephambanayo yengilazi enezimbambo | |

| Ingilazi yobuso kanye nengilazi enezimbambo kuxhunywe i-silicone structural sealant ekhanyayo, futhi ukwelashwa kwendawo ephambanayo yengilazi enezimbambo kanje:Uhlobo lwangemuva, uhlobo lomthungo Okhweziwe, Uhlobo lwe-Flush, Uhlobo oluphumayo. |

Uhlobo lwangemuva

Ubambo lwengilazi lutholakala ngemuva kwengilazi yobuso, luboshwe engilazini yobuso nge-adhesive yesakhiwo iyonke.

Uhlobo lwe-flush

Ubambo lwengilazi lutholakala phakathi kwezingilazi ezimbili zobuso, uhlangothi olulodwa lwezimbambo lugcwele ubuso bengilazi yobuso, futhi ingcina yesakhiwo isetshenziswa phakathi kwezimbambo nezingilazi ezimbili zobuso.Kungaba khona ukushintshashintsha kwe-chromatic embonweni ngenxa yogqinsi oluhlukile lokudluliswa kwe-lateral

Uhlobo lomthungo ogingqiwe

Ubambo lwengilazi lutholakala ekuhlanganyeleni kwengilazi yobuso obubili, futhi izingcezu ezintathu zengilazi zixhunywe kanye neglue yesakhiwo.

Uhlobo oluphumayo

Ubambo lwengilazi luphakathi kwengilazi yobuso obubili, izinhlangothi zombili ziphuma phezulu kwengilazi yobuso, izimbambo nengilazi yobuso kuvaliwe ngokunamathela kwesakhiwo.

Ukulungiswa kwengilazi eyizimbambo egcwele ingilazi engaphambili

Ingilazi enezimbambo egcwele udonga lwamakhethini engilazi

Uhlobo olulengayo olugcwele udonga lwamakhethini engilazi

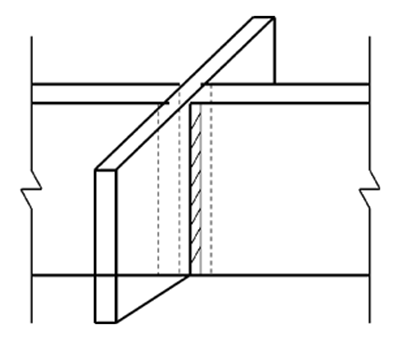

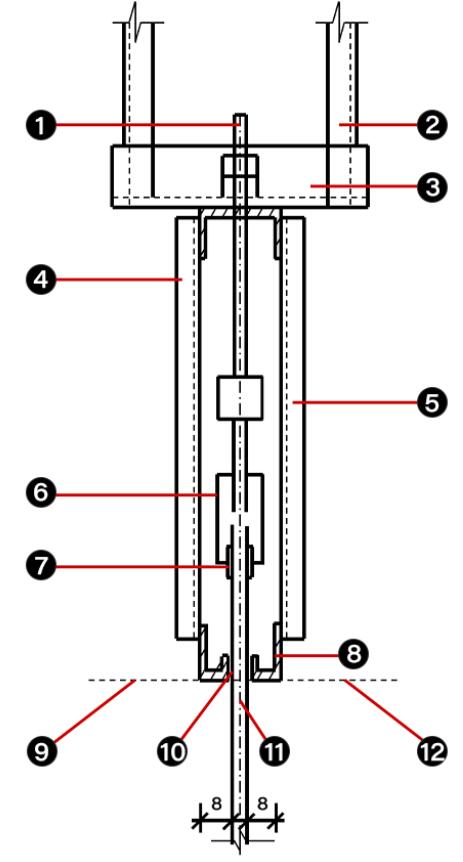

I-node evundlile yodonga lwekhethini lwengilazi enezimbambo zonke

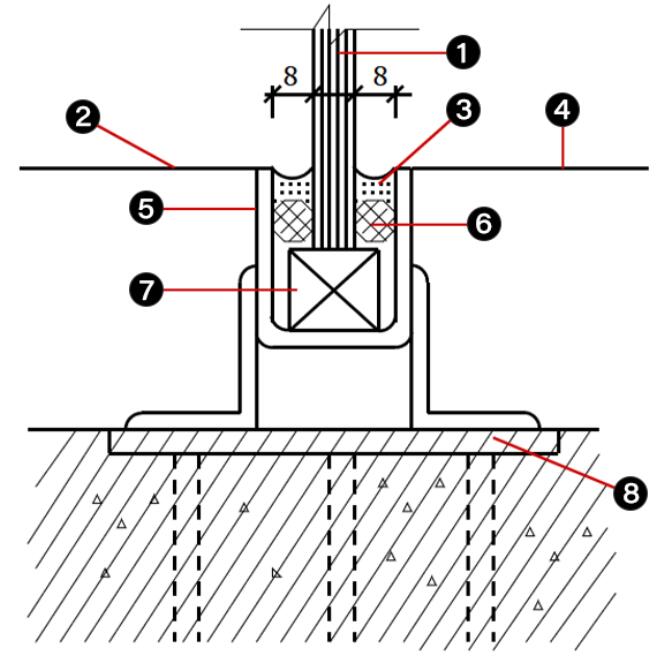

1. Ingilazi eshisayo;2. Umbambo wengilazi oshisayo;3. Insimbi engagqwali elenga uhlelo lokubopha;

4. Ulayini wophahla lwangaphakathi;5. Ingcina yengilazi yesakhiwo

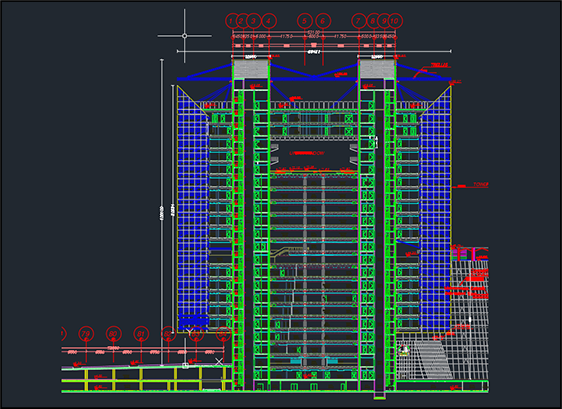

1.Uhlobo olulengayo olugcwele ingilazi yodonga lwamakhethini

Isakhiwo sokulenga udonga lwamakhethini engilazi ikakhulukazi sakhiwe izingxenye ezintathu:

I-1.Isakhiwo sokulenga esithwala imithwalo esiphezulu: i-hanger yensimbi, imishayo yensimbi, i-hanger yokumiswa, i-horseshoe yokulenga, ukulenga ithusi le-clamp, isiqeshana sensimbi sangaphakathi nangaphandle, ukugcwalisa nokufaka uphawu, i-silicone sealant ephikisana nesimo sezulu.

2.Isakhiwo sengilazi esiphakathi: iphaneli yengilazi;Ipuleti lezimbambo zengilazi, i-silicone structural sealant.

I-3.Isakhiwo sefreyimu ephansi: uhlaka lwensimbi, i-neoprene rubber pad, izinto zokugcwalisa igwebu, i-sealant ephikisana nesimo sezulu.

Ukufakwa kwe-1.Bolt;2. ubakaki olengayo wensimbi;

3.Insimbi yensimbi;4.Isiqeshana sensimbi sangaphandle;

5.Isiqeshana sensimbi sangaphakathi;6.Izihlilingi;

7.Ipuleti le-Suspension clamp;8.3mm SS iphrofayili yensimbi yesiteshi;

9.Ukuphela kwangaphandle;10.Silicone sealant;ingilazi engu-11.19 mm;

12.Uphahla lwangaphakathi;

Umdwebo we-node engenhla yohlobo olulengayo olugcwele udonga lwamakhethini engilazi

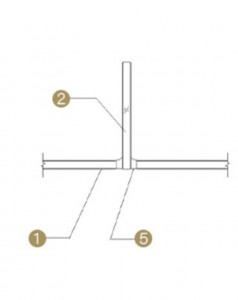

Umdwebo wenodi yozimele

ingilazi engu-1.19 mm;

2.Ukuphela kwangaphandle;

3.Silicone sealant;

4.Indawo yangaphakathi;

Iphrofayili yensimbi yesiteshi esingu-5.3mm SS;

6.Izinto zokugcwalisa igwebu;

7.I-Neoprene spacer;

8.Izingxenye ezishunyekiwe;

1. Igebe eliphakathi kodonga oluzungezile lwegroove evalekile kanye nephaneli yengilazi noma ubambo lwengilazi akufanele libe ngaphansi kuka-8mm, igebe phakathi komkhawulo ophansi wengilazi elengayo kanye naphansi komsele ongezansi kufanele uhlangabezane nezidingo zokuguqulwa kwengilazi elongation. .Ingilazi kanye nephansi le-groove ephansi kufanele isekelwe noma igcwaliswe ngephedi yokunwebeka futhi ubude bephedi akufanele bube ngaphansi kuka-100mm, ubukhulu bungabi ngaphansi kuka-10mm, Kufanele ivalwe nge-silicone building sealant phakathi kodonga lwamaseli. kanye nengilazi.

I-2.Ubuso bodonga lwamakhethini engilazi olugcwele akumele luhlangane ngqo nezinye izinto eziqinile.Igebe phakathi kwendawo yepuleti nendawo yomhlobiso noma indawo yesakhiwo akufanele ibe ngaphansi kuka-8mm, futhi ivalwe nge-sealant.

2.Isakhiwo esilengayo esingaphezulu

1.Isiphanyeko sensimbi nesigxobo

Ikakhulukazi khetha insimbi yesakhiwo, amaphaneli engilazi nezimbambo zengilazi nezinye izingxenye zomthwalo wazo omkhulu nomthwalo womoya odluliselwe esakhiweni esiyinhloko.

2.Isigxobo esilengayo, isicathulo samahhashi esilengayo kanye neshidi lethusi elilengayo

Ngokusho kobukhulu bomthwalo wokumiswa, isigxobo sokulenga kanye nesici sokulenga sihlukaniswe ngohlobo olujwayelekile nolunzima

| Ukukhethwa kwempahla yokuphakamisa kanye netafula lereferensi yendawo yokwakha edingekayo | ||

| Ukumelana nekhwalithi yengilazi elengayo(KG) | Uhlobo lokulenga | Ubude bokwakha okudingekayo(MM) |

| Wg <450 | Okujwayelekile | >450 |

| 450≤Wg≤1200 | Uhlobo olunzima | >550 |

3.Izinsimbi zensimbi zangaphakathi nangaphandle

Izinsimbi zensimbi zangaphakathi nangaphandle ziyizakhiwo zokuvala unqenqema engxenyeni engenhla yodonga lwamakhethini engilazi ngemva kokumiswa kwengilazi, kungcono ukhethe insimbi engagqwali.

Umsebenzi

Ingilazi ibekwe engxenyeni engenhla, ukuze ingilazi yobuso idluliselwe ngokulinganayo engilazini yezimbambo kanye ne-hanger yensimbi ngemva kokuthwala umthwalo womoya.Ngesikhathi esifanayo, kuphinde kube yindawo yokuhlangana nokuvala yophahla olumisiwe lwangaphakathi kanye nezinto zokuhlobisa zangaphandle kanye nodonga lwamakhethini engilazi egcwele.

Ukufakwa

Ukuze uphakamise ingilazi yobuso endaweni yayo, lungisa isiqeshana sensimbi sangaphakathi kuqala, bese ulungisa isiqeshana sensimbi sangaphandle ngebhawodi yokufaka ngemva kokuba ingilazi imisiwe.

3.Ukucaciswa kwezinto ezibonakalayo nokusebenza kobuchwepheshe

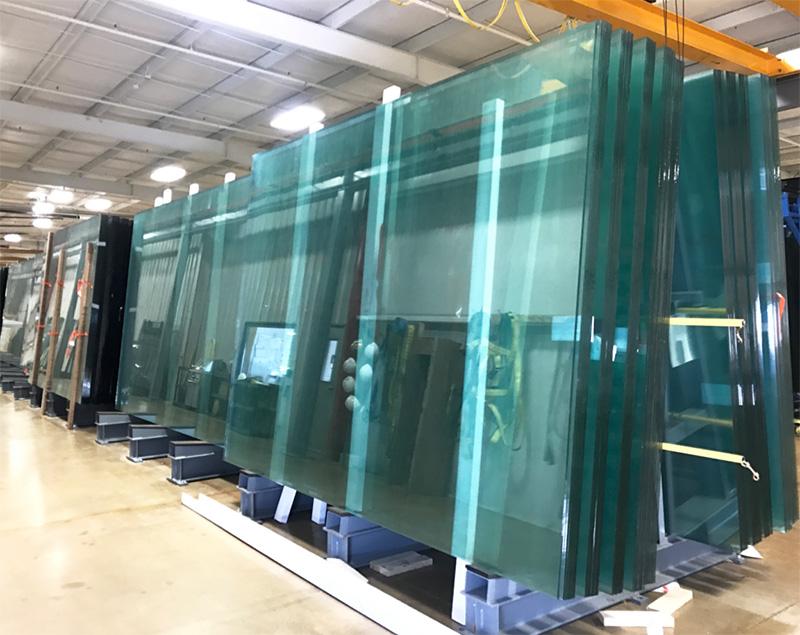

Ingilazi

1.Uhlobo:

ingilazi epholile, ingilazi epholile e-laminated njll.

2.Ubukhulu:

ngokuklama nokubala ukunquma, okuvame ukusetshenziswa kakhulu ngu-12/19mm.

3. Ukwelashwa kwe-Edge:

kufanele iphuculwe futhi ivimbele izikhala ezincane ngemuva kokusika ingilazi, igebe kulula ukwenza umphumela wokuhlushwa wokucindezeleka ekuqhekekeni kwengilazi.

1.Isibalo samandla:

I-adhesive yesakhiwo se-silicone isetshenziswa phakathi kwengilazi yobuso kanye nengilazi enezimbambo, ububanzi nobukhulu bokuhlangana okunamathelayo kufanele kuhlolwe ngamandla.

2.I-Sealant:

I-silicone sealant engathathi hlangothi kufanele isetshenziswe phakathi kwengilazi nohlaka lwensimbi kanye nebhande.

I-Silicone structure sealant

Uhlaka lwensimbi

Kuphrojekthi yodonga lwamakhethini ohlobo olulengayo, uhlaka lwensimbi olugqitshwe ngezansi noma odongeni kungcono ukusebenzisa uhlaka lwensimbi oluwugqinsi oluwu-3mm lwensimbi engagqwali.

Ukufakwa kanye nenqubo yokwakha yokulenga udonga lwamakhethini engilazi

Inkokhelo → Ukufakwa kwesakhiwo sensimbi enesisindo esiphezulu → Ukukhwezwa kohlaka oluphansi nolusemaceleni → Ukufakwa kwengilazi → Faka iglue bese uvala → Hlanza futhi uhlole

Amaphuzu abalulekile wokufaka

1.Ukuma

1. I-eksisi yokuma kodonga lwekhethini yokulinganisa nokubeka kumele ihambisane noma ime mpo ne-axis yesakhiwo esikhulu, ukuze kugwenywe ukungqubuzana phakathi kokwakhiwa kodonga lwamakhethini kanye nokwakhiwa komhlobiso wangaphakathi nangaphandle, okuholela ekulimaleni kwe-Yin ne-Yang. I-engeli ayisona isikwele futhi indawo yokuhlobisa ayihambelani.

2. Sebenzisa izinga eliphezulu lokunemba kwelaser, i-theodolite, fanisa kutheyiphu yensimbi evamile, isando, irula yeleveli ukuze uhlole kabusha.Ngodonga lwamakhethini olunobude obungaphezu kuka-7m, kufanele lulinganiswe futhi luhlolwe kabili ukuze kuqinisekiswe ukunemba okuqondile kodonga lwamakhethini.Ukuchezuka phakathi kwemigqa ephakathi nendawo engenhla nangaphansi kufanele ibe ngaphansi kuka-1 mm kuya ku-2mm.

3. Ukulinganisa okulinganiselwe kuzokwenziwa lapho amandla omoya engekhulu kune-4, iphutha phakathi kwezintambo zangempela kanye nomdwebo womklamo kufanele ulungiswe, usatshalaliswe futhi ugaywe, awukwazi ukuqongelela.Ngokuvamile ixazululwa ngokulungisa ububanzi begebe nokuma kohlaka.Uma iphutha losayizi likhulu, bonisa ngesikhathi, futhi wenze kabusha ingilazi noma usebenzise esinye isisombululo esinengqondo.

5. Udonga lwamakhethini lwengilazi yonke lulungisa ingilazi ngqo esakhiweni esiyinhloko, okokuqala gxuma ingilazi phansi, bese inquma indawo yokubambelela ngokosayizi wangaphandle wonqenqema.

I-2.Ukufakwa kwesakhiwo sensimbi ephezulu

1. Naka ukuthi uhlole ingxenye eshumekiwe noma ipuleti lensimbi lokunamathisela ukuthi liqinile, ikhwalithi yebhawodi okusetshenzwa kulengwa kuyo kufanele ithembeke, indawo yebhawodi okusetshenzwa kulengwa kuyo akufanele ibe seduze konqenqema lwelungu likakhonkolo eliqinisiwe, ububanzi nokujula kwe-borehole. kufanele ihlangabezane nemibandela yobuchwepheshe yomkhiqizi webhawudi lehange, umlotha wembobo kufanele uhlanzwe.

2. Indawo yokufaka nokuphakama kwengxenye ngayinye kufanele kuqhubeke ngokuqinile ngokuhambisana nezidingo zokuma kwezintambo kanye nemidwebo yokuklama.Okubaluleke kakhulu ukuthi umugqa omaphakathi wensimbi ethwala umthwalo kufanele uhambisane nomugqa omaphakathi wodonga lwamakhethini, futhi isikhungo sembobo yesikulufu esiyi-elliptical kufanele sihambisane nendawo ye-derrick bolt eklanyelwe.

3. Ukufakwa kwesiqeshana sensimbi yangaphakathi kufanele kube bushelelezi futhi kuqonde.Kudingekile ukusebenzisa umugqa wokudonsa ngokusebenzisa isigatshana ukuze uhlole futhi uqondise ukuphambuka okubangelwa ukushisela.I-clamp yensimbi yangaphandle kufanele ihlanganiswe ngokuvumelana nenombolo ye-serial, futhi idinga ukuqondisa.Ukuhlukaniswa kweziqeshana zensimbi zangaphakathi nangaphandle kufanele kufane futhi usayizi kufanele uhlangabezane nezidingo zomklamo.usayizi.

3.Uzimele ongaphansi kanye nokukhwezwa kozimele oseceleni

Ukwakhiwa ngokuhambisana nokuma kwezintambo kanye nokuphakama kwedizayini, yonke indawo yesakhiwo sensimbi kanye nebhulashi elihlanganisiwe lokushisela ngopende ophikisana nokugqwala.Hlanza ukungcola ngaphakathi komngcele ophansi.Okungenani amaphedi we-neoprene ama-2 kufanele abekwe phansi kwengilazi ngayinye, futhi ubude akumele bube ngaphansi kuka-100mm.

4.Ukufakwa kwengilazi

Ukuphakanyiswa kwengilazi nokubekwa kuzokwenziwa ngokuhambisana ngokuqinile nenqubo yokwakhiwa kwesayithi

5.I-Silicone Sealant Umjovo Nokuhlanza

Ubukhulu bokwakhiwa kwe-silicone sealant emelana nesimo sezulu kufanele bube phakathi kuka-3.5 ~ 4.5mm, amajoyinti ama-sealant azacile kakhulu awalungele ikhwalithi yokuvala futhi avimbele imvula.Ngaphezu kwalokho, umjovo weglue akufanele wenziwe ekushiseni okuphansi okungaphansi kuka-5 ℃, ngoba izinga lokushisa liphansi kakhulu, ingcina izogeleza, ibambezele isikhathi sokuphulukisa, futhi ithinte ngisho namandla aqinile.Namathisela itheyiphu yokunamathela endaweni ehlangene ukuze uvimbele ijeli ye-silica ukuthi ingangcolisi ingilazi.Ukwakhiwa komjovo wenjoloba ochwepheshe.Ngemuva komjovo weglue, sebenzisa amathuluzi akhethekile ukuze usule i-glue, yenza i-glue seam ibe ngaphezulu kwe-concave.Ingilazi nensimbi yengxenye yomjovo weglue kufanele kusulwe kuhlanzeke nge-acetone noma okokuhlanza okukhethekile, ungasebenzisi indwangu emanzi namanzi.

Ukupakisha nokuthunyelwa

Idizayini eyenziwe ngokwezifiso yamahhala

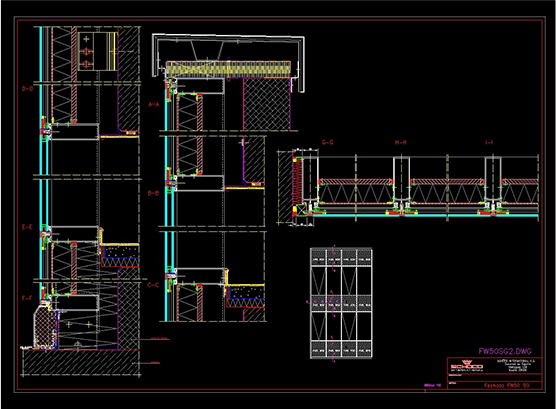

Siklama izakhiwo zezimboni eziyinkimbinkimbi zamakhasimende asebenzisa i-AutoCAD, PKPM, MTS, 3D3S, Tarch, Tekla Structures(Xsteel) nokunye.

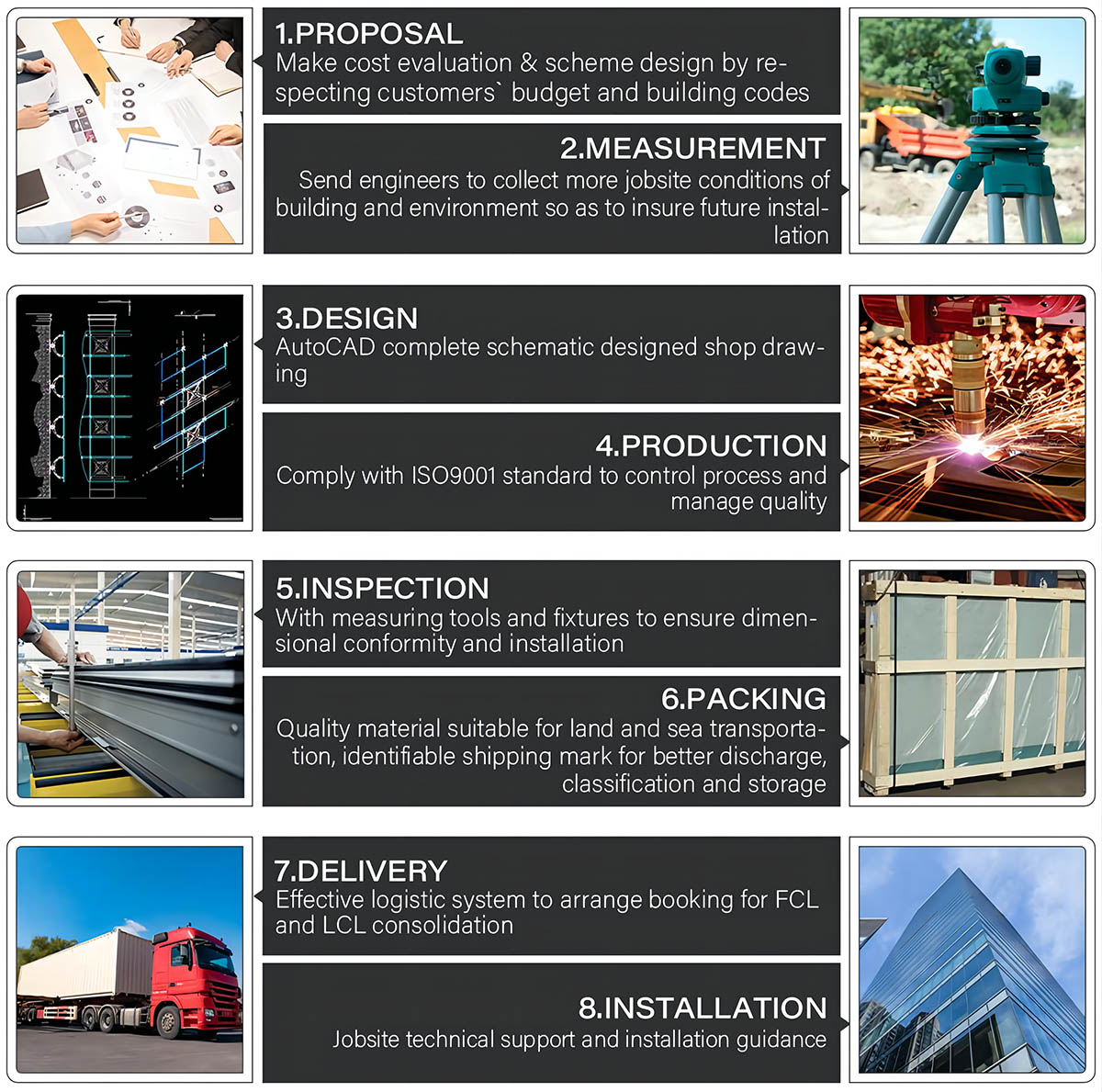

Inqubo yokwenza ngokwezifiso

Uhlolojikelele lweworkshop yokukhiqiza

I-Iron Workshop

I-Raw Material Zone 1

I-workshop ye-aluminium alloy

I-Raw Material Zone 2

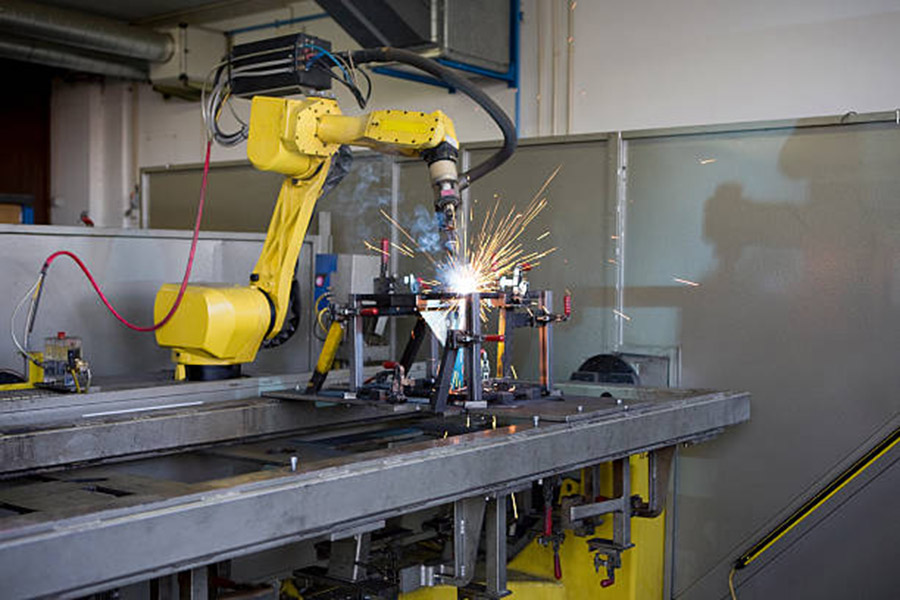

Umshini wokushisela wamarobhothi ofakwe efektri entsha.

I-Automatic Spraying Area

Imishini yokusika eminingi

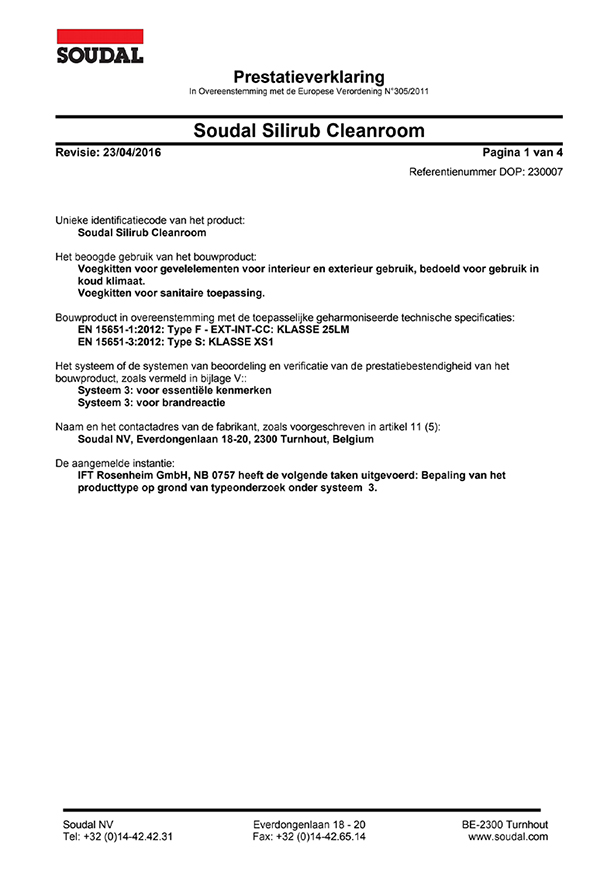

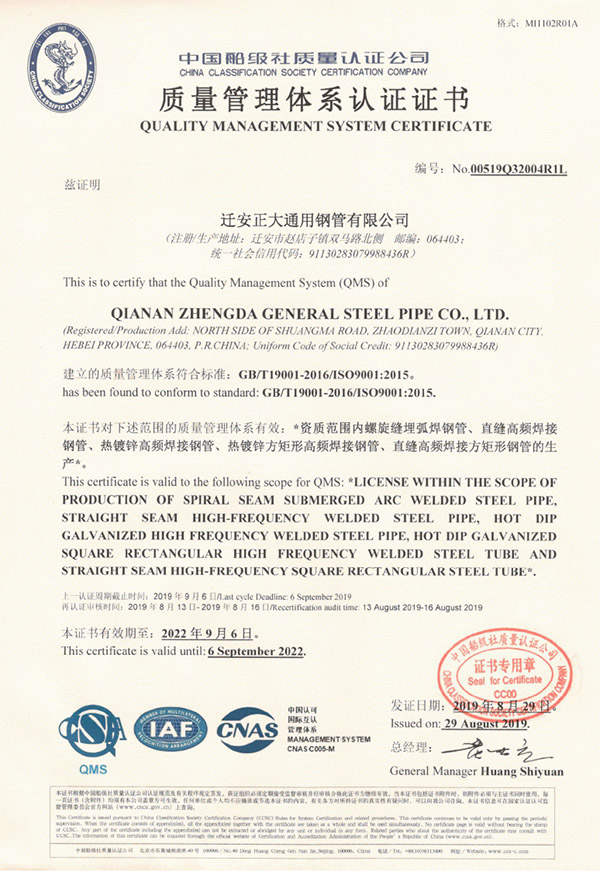

Igunya lesitifiketi

I-FAQ

1.Yini isikhathi sakho sokukhiqiza?

Izinsuku ezingama-38-45 zincike ekukhokhweni okutholiwe kanye nokusayinwa komdwebo wesitolo

2. Yini eyenza imikhiqizo yakho ihluke komunye umphakeli?

Ukulawulwa kwekhwalithi ngokuqinile kanye nentengo encintisana kakhulu kanye nezinsizakalo zobunjiniyela zokuthengisa nokufakwa.

3. Isiphi isiqiniseko sekhwalithi osinikezile futhi uyilawula kanjani ikhwalithi?

Kusungulwe inqubo yokuhlola imikhiqizo kuzo zonke izigaba zenqubo yokukhiqiza - izinto zokusetshenziswa, ezisetshenziswayo, izinto eziqinisekisiwe noma ezihloliwe, izimpahla eziqediwe, njll.

4. Ungayithola kanjani ikhotheshini enembile?

Uma ungakwazi ukunikeza idatha yephrojekthi elandelayo, siyakwazi ukukunikeza ikhotheshini enembile.

Ikhodi yokuklama/ indinganiso yokuklama

Indawo yekholomu

Isivinini somoya esiphezulu

Umthwalo wokuzamazama komhlaba

Isivinini esikhulu seqhwa

Imvula enkulu

Inkampani yokubambisana